Operator and Management Support for Improving Energy and Material Efficiency in the Chemical Industry

Chemical plants are important consumers of energy and of feedstock and auxiliary materials. Operating them in the most energy- and resource-efficient manner has been the focus of the industry for a long time but there is still room for improvement.

Prof. Dr.-Ing. Stefan Krämer, Bayer AG, TU Dortmund

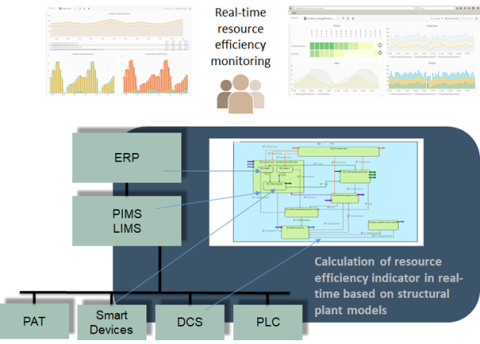

Here, strategies are explored to enhance the resource efficiency in chemical production processes by monitoring and displaying information about the resource efficiency in real time. The concepts of resource efficiency indicators and baselines are summarized and the computation of the best demonstrated practice from historical data is described which points out improvement potential to the plant operators and engineers. A software platform for the calculation of the indicators in large industrial sites based on structural models is presented. Results of the implementation at two major industrial production sites are presented which exemplarily demonstrate the benefits of the approach.

Prof. Dr.-Ing. Stefan Krämer, Bayer AG, TU Dortmund, Department of Biochemical and Chemical Engineering

[email protected]

DOI: 10.1002/cite.70014