An Upscaling Method in Drying System Design: From Single Sample Kinetic to Dryer Models

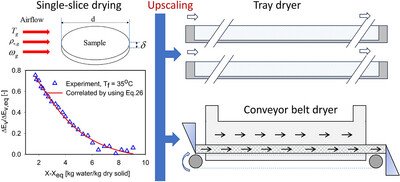

An upscaling methodology for designing convective drying systems is presented, specifically focusing on tray and belt dryers of sliced food.

Autor: Assoc. Prof. Kieu Hiep Le, School of Mechanical Engineering, Hanoi University of Science and Technology

Based on the convective drying history of a single food slice, a semi-empirical model, named the Reaction Engineering Approach (REA) model, is developed to describe the heat and mass interaction between the food and drying agent. The model is integrated into the belt dryer's energy and mass conservation equations for co-current and counter-current configurations. The results indicate a remarkable maldistribution of air temperature and relative humidity along the belt and tray length, leading to a significant variation of the drying rate. The drying time and the moisture content uniformity are strongly dependent on the airflow and product flow configurations. The methodology proposed in this work can help design and operate the drying system accurately by knowing the single sample drying kinetics.

Assoc. Prof. Kieu Hiep Le, School of Mechanical Engineering, Hanoi University of Science and Technology

[email protected]