Applying Quality by Design to Digital Twin Supported Scale-Up in Modular Plants

In the pharmaceutical and specialty chemical industries, faster time-to-process is a significant measure of success.

Amy Koch, TU Dresden, Process-to-Order Group

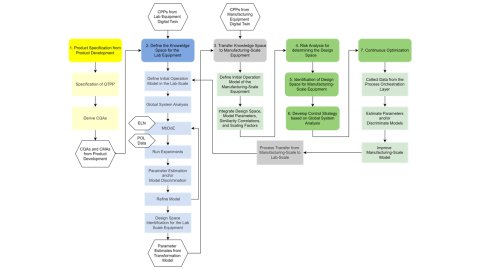

Modular Plants made up of Process Equipment Assemblies are of significant interest due to high flexibility and good scalability. Additional benefit can be leveraged from equipment-based Digital Twins combined with methodologies such as Quality by Design (QbD). In 2024, a small survey, aimed at stakeholders in the modular plant community, was launched to address FAIR information in process development domains. Responses from professionals in multiple disciplines revealed critical gaps in information during the lifecycle of modular manufacturing systems. These insights informed the development of a Digital Twin-based workflow for scale-up in Modular Plants, incorporating principles of QbD. Key aspects of this workflow are illustrated for transfer of an esterification process from a 2-L to a 50-L reactor module.