Challenges in the Recycling of Battery Casing Materials

Autorin: Malena Staudacher, TU Bergakademie Freiberg, Institute for Mechanical Process Engineering and Mineral Processing, Freiberg

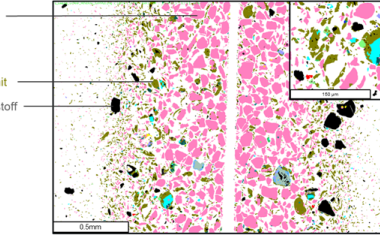

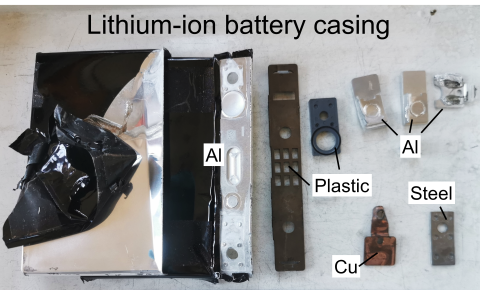

Research Article | Current recycling methods for lithium-ion batteries (LIBs) focus on recovering valuable metals such as cobalt and nickel for economic reasons. Yet, the cell casing components, mainly aluminum, can significantly contribute to achieving political recycling targets. Mechanical processes are used to separate the casing components from the overall LIB material stream. The aluminum, copper, steel, and plastic components are then further concentrated into various potential products by, e.g., magnetic separation, eddy current separation, and air classification. Considering the benefits of additional stress to compact the metal parts, the knowledge gained from the individual sorting steps can be combined to form a process flow chart.