Dynamic Life Cycle Assessment of Integrated Production of Steel and Methanol

Autor: Ankur Gaikwad, Fraunhofer Institute for Environmental, Safety and Energy Technology UMSICHT, Oberhausen

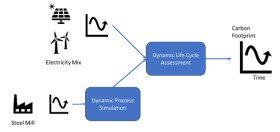

Research Article | The dynamic carbon footprint profile of methanol production from steel mill gases is affected by fluctuations of steel mill gas flow rates and compositions, as well as the composition of electricity mix. The cross-industrial network of steel mill, gas conditioning, hydrogen production, chemical synthesis, and power generation was simulated under dynamic conditions. Dynamic life cycle assessment (LCA) was carried out and indicated that the CO2 emissions in a power plant, electrolytic hydrogen demand, and variations in electricity mix were the major drivers of the fluctuations in the total carbon footprint. Dynamic LCA is useful for quantifying temporal uncertainty in environmental impacts. This insight can be used to analyze uncertainty in impacts for downstream products, processes, and use cases.