Foundation Model for Determining Suitable Process Parameters in Twin-Screw Extrusion

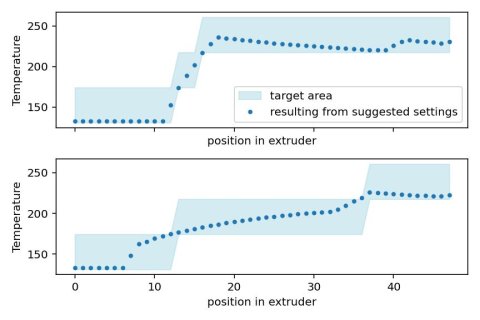

Extrusion is a complex process, and identifying suitable process parameters to achieve specific product or process properties is often a time-consuming manual task, which hinders automation and requires specialized staff.

Julia Burr, Fraunhofer ITWM

Machine learning models present a promising solution, but they typically require large amounts of high-variational data for training to achieve satisfactory precision. To address this challenge, we propose the development of a foundation model for co-rotating twin-screw extruders, leveraging extensive simulated data for training. By employing a transformer architecture combined with a masking technique, this model will be capable of suggesting process parameters based on desired outcomes. We will also demonstrate how this model can be effectively fine-tuned for a specific extrusion plant using minimal data.

Julia Burr, Fraunhofer ITWM, Fraunhofer-Platz 1, Kaiserslautern, 67663 Germany

[email protected]

DOI: 10.1002/cite.70017